Pulse-20 9 Degrees of freedom inertial measurement unit

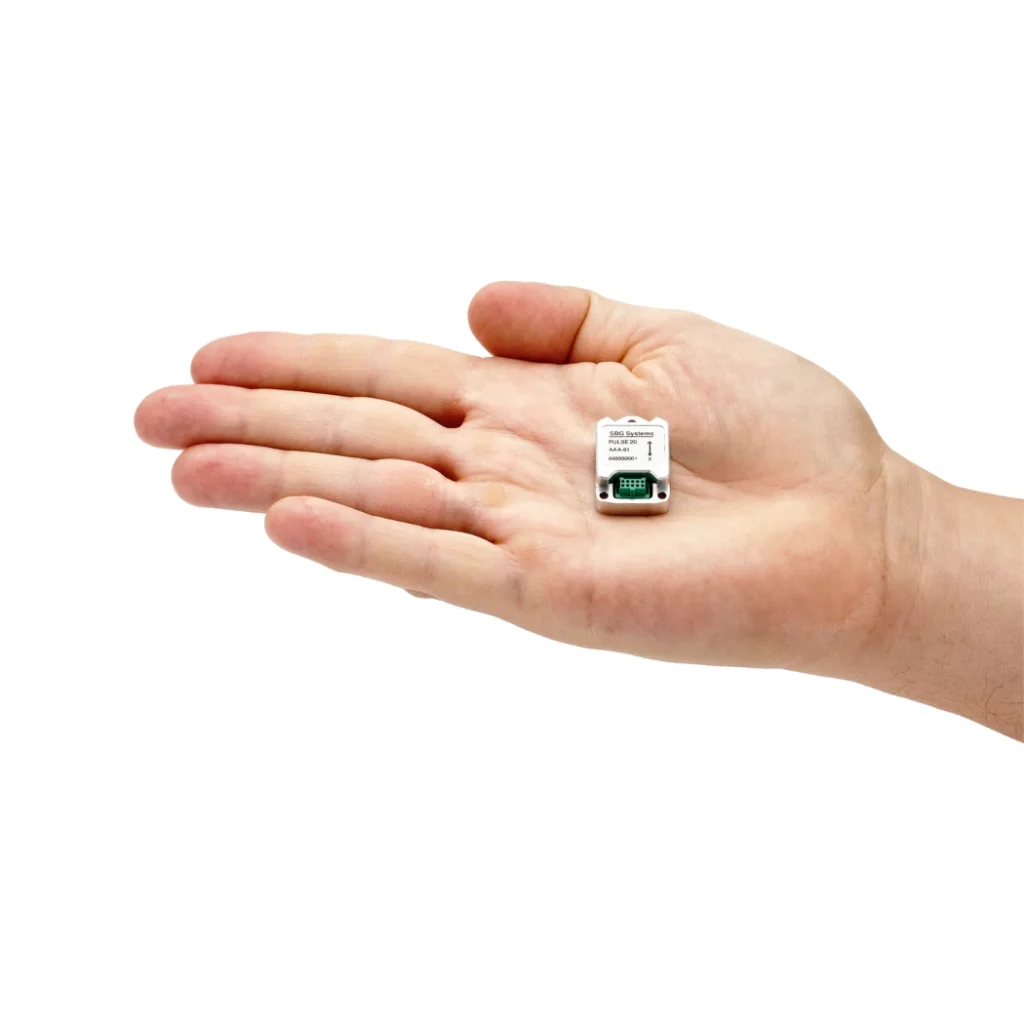

Pulse-20 is the most compact fully calibrated industrial grade 9 DoF IMU.

With its sub-miniature design, it can be integrated in multiple different types of vehicles, from civilian and subsea navigation to defense applications. It is also very robust to environmental constraints, with unmatched survivability in shocks, robustness in vibrations and maintains outstanding performance in all conditions.

Pulse-20 is, therefore, the best motion sensors for space constrained applications with tough environmental conditions.

Discover all its features and applications.

Specifications

Accelerometer performance

±40 g Long term bias repeatability

1500 μg * Bias in-run instability

14 μg ** Scale factor

100 ppm * Velocity random walk

0.03 m/s/√h ** Vibration rectification error

0.05 mg/g² Bandwidth

390 Hz

Gyroscope performance

± 1000 °/s Long term bias repeatability

750 °/h * Bias in-run instability

7 °/h ** Scale factor

500 ppm * Angular random walk

0.018 °/√h ** Vibration rectification error

<1 °/h/g² *** Bandwidth

133 Hz

Magnetometer performance

50 Gauss Bias in-run instability

1.5 mGauss Random walk

3 mGauss Bandwidth

22 Hz

Interfaces

Binary sbgECom Output rate

Up to 2kHz Serial ports

1x RS422 CAN

1x CAN 2.0 A/B, up to 1 Mbps Sync OUT

1 x Synchronization output Sync IN

1x Clock Input Clock modes

Internal, External Direct (2kHz), External Scaled (1Hz to 1kHz) IMU configuration

sbgECom, sbgCenter (ODR, sync in/out, events)

Mechanical & electrical specifications

4 to 15 VDC Power consumption

400 mW Weight

10 g Dimensions (LxWxH)

26.8 mm x 18.8 mm x 9.5 mm

Environmental specifications & operating range

IP-50 Operating temperature

-40 °C to 85 °C Vibrations

10 g RMS | 20 Hz to 2 kHz Shocks

< 2000 g MTBF (computed)

50 000 hours Compliant with

MIL-STD-810

Applications

The Pulse-20 provides precise attitude and heading data in a compact, high-performance package suited for a wide range of applications.

For airborne navigation, it ensures stable flight control with lightweight precision, even in tough conditions. In land navigation, it enhances sensor fusion and orientation, enabling smooth vehicle movement.

Adaptable and resilient, our IMU is the go-to solution for industries needing compact, powerful orientation sensors.

Discover its full range of applications and elevate your project’s capabilities.

Pulse-20 datasheet

Get all the sensor features and specifications delivered straight to your inbox!

Compare Pulse-20 with other products

Explore how the Pulse-20 stacks up against other products with our comprehensive comparison table. Discover the unique advantages it offers in performance, precision, and compact design, making it a standout choice for your orientation and navigation needs.

Pulse-20 |

|||

|---|---|---|---|

| Accelerometer Range | Accelerometer Range ± 40 g | Accelerometer Range ±40 g | Accelerometer Range ±15 / ±40 g |

| Gyroscope Range | Gyroscope Range ± 1000 °/s | Gyroscope Range ± 2000 °/s | Gyroscope Range ± 400 °/s |

| Accelerometer Bias in-run instability | Accelerometer Bias in-run instability 14 μg | Accelerometer Bias in-run instability 6 μg | Accelerometer Bias in-run instability 6 μg |

| Gyroscope Bias in-run instability | Gyroscope Bias in-run instability 7 °/h | Gyroscope Bias in-run instability 0.8 °/h | Gyroscope Bias in-run instability 0.1 °/h |

| Velocity Random Walk | Velocity Random Walk 0.03 m/s/√h | Velocity Random Walk 0.02 m/s/√h | Velocity Random Walk 0.02 m/s/√h |

| Angular Random Walk | Angular Random Walk 0.018 °/√h | Angular Random Walk 0.08 °/√h | Angular Random Walk 0.012 °/√h |

| Accelerometer Bandwidth | Accelerometer Bandwidth 390 Hz | Accelerometer Bandwidth 480 Hz | Accelerometer Bandwidth 100 Hz |

| Gyroscope Bandwidth | Gyroscope Bandwidth 133 Hz | Gyroscope Bandwidth 480 Hz | Gyroscope Bandwidth 100 Hz |

| Output rate | Output rate Up to 1kHz | Output rate Up to 2kHz | Output rate Up to 2 kHz |

| Operating voltage | Operating voltage 4 to 15 VDC | Operating voltage 3.3 to 5.5 VDC | Operating voltage 5 to 36 VDC |

| Power consumption | Power consumption 0.40 W | Power consumption 0.30 W | Power consumption < 1.8 W |

| Weight (g) | Weight (g) 10 g | Weight (g) 12 g | Weight (g) 260 g |

| Dimensions (LxWxH) | Dimensions (LxWxH) 26.8 x 18.8 x 9.5 mm | Dimensions (LxWxH) 30 x 28 x 13.3 mm | Dimensions (LxWxH) 56 x 56 x 50.5 mm |

Compatibility

Documentation of Pulse-20

Pulse-20 comes with comprehensive documentation, designed to support users at every step.

From installation guides to advanced configuration and troubleshooting, our clear and detailed manuals ensure smooth integration and operation.

Production process

Discover the precision and expertise behind every SBG Systems products. This following video offers an inside look at how we meticulously design, manufacture, and test our high-performance inertial systems.

From advanced engineering to rigorous quality control, our production process ensures that each product meets the highest standards of reliability and accuracy.

Watch now to learn more!

Ask for a quotation

Do you have questions?

Welcome to our FAQ section, where we address your most pressing questions about our cutting-edge technology and its applications. Here, you’ll find comprehensive answers regarding product features (pulse series), installation processes, troubleshooting tips, and best practices to maximize your experience. Whether you’re a new user seeking guidance or an experienced professional looking for advanced insights, our FAQs are designed to provide the information you need.

Find Your Answers Here!

What is the difference between IMU and INS?

The difference between an Inertial Measurement Unit (IMU) and an Inertial Navigation System (INS) lies in their functionality and complexity.

An IMU (inertial measuring unit) provides raw data on the vehicle’s linear acceleration and angular velocity, measured by accelerometers and gyroscopes. It supplies information on roll, pitch, yaw, and motion, but does not compute position or navigation data. The IMU is specifically designed to relay essential data about movement and orientation for external processing to determine position or velocity.

On the other hand, an INS (inertial navigation system) combines IMU data with advanced algorithms to calculate a vehicle’s position, velocity, and orientation over time. It incorporates navigation algorithms like Kalman filtering for sensor fusion and integration. An INS supplies real-time navigation data, including position, velocity, and orientation, without relying on external positioning systems like GNSS.

This navigation system is typically utilized in applications that require comprehensive navigation solutions, particularly in GNSS-denied environments, such as military UAVs, ships, and submarines.

What is an Inertial Measurement Unit?

Inertial Measurement Units (IMUs) are sophisticated devices that measure and report a body’s specific force, angular velocity, and sometimes magnetic field orientation. IMUs are crucial components in various applications, including navigation, robotics, and motion tracking. Here’s a closer look at their key features and functions:

- Accelerometers: Measure linear acceleration along one or more axes. They provide data about how quickly an object is speeding up or slowing down and can detect changes in motion or position.

- Gyroscopes: Measure angular velocity, or the rate of rotation around a specific axis. Gyroscopes help determine orientation changes, enabling devices to maintain their position relative to a reference frame.

- Magnetometers (optional): Some IMUs include magnetometers, which measure the strength and direction of magnetic fields. This data can help determine the device’s orientation relative to the Earth’s magnetic field, enhancing navigational accuracy.

IMUs provide continuous data on an object’s motion, allowing for real-time tracking of its position and orientation. This information is critical for applications like drones, vehicles, and robotics.

In applications such as camera gimbals or UAVs, IMUs help stabilize movements by compensating for unwanted motions or vibrations, resulting in smoother operations.