Heave refers to the vertical motion of a vessel or platform caused by ocean waves. Unlike pitch or roll, which involve rotational movement, heave involves up-and-down displacement. Unlike pitch or roll, which involve angular motion, heave is strictly vertical. Heave is a critical factor in navigation and offshore operations. Excessive heave can directly impact vessel stability, accuracy and crew safety.

Wave height is the primary factor influencing heave. Larger waves generate stronger vertical displacement, increasing motion amplitude. Wave period also affects heave characteristics. Longer periods result in smoother vertical motion, whereas shorter periods result in rapid oscillations. Wave direction modifies how heave is experienced. Waves approaching from the bow or stern have a different effect to those striking the sides. Vessel design also plays a crucial role in the way a vessel responds to heave. The hull’s shape, displacement and weight distribution determine how motion is absorbed.

Heave significantly impacts vessel stability. Continuous vertical oscillations affect comfort, equipment performance and safety. For smaller vessels, strong heave can create dangerous conditions. In offshore operations, it poses challenges to drilling and platform stability. Vertical movements can interfere with the operation of the drill string and seabed anchoring. Accurate compensation systems are therefore essential for offshore activities.

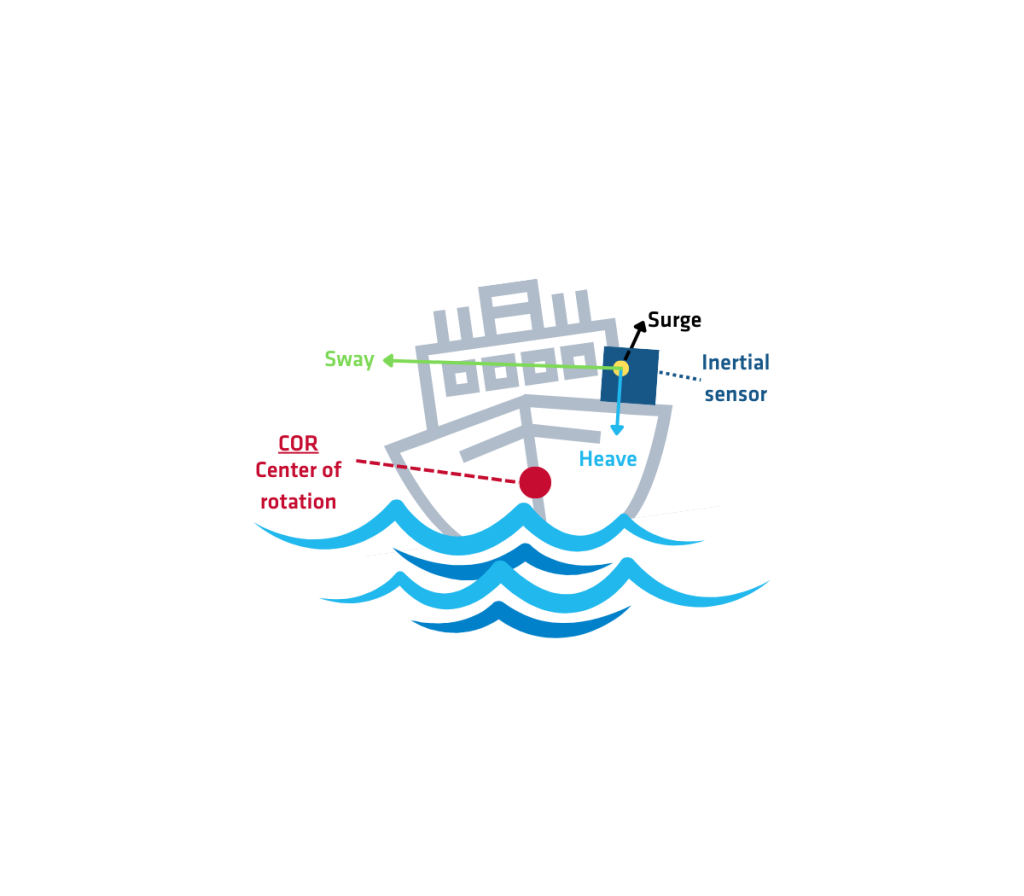

It also affects navigation accuracy. Vertical displacement affects precise positioning during docking, surveying or construction. Motion disturbs GNSS and inertial measurements, necessitating advanced corrections. Accurate monitoring is therefore critical to mission success.

Best heave measurement methods and technologies

Advanced measurement tools provide accurate data. Accelerometers, wave sensors and motion units deliver real-time monitoring. Understanding and managing the vertical movement of a vessel is essential for ensuring the safety, stability and efficiency of maritime and offshore operations.

Several methods and technologies are used to correct discrepancies:

1 – Real-Time Heave Compensation

Sensors such as accelerometers, gyroscopes, and GNSS-coupled INS measure vessel motion in real time. The system calculates heave displacement and applies corrections immediately to equipment, such as echo sounders or drilling risers.

2 – Delayed heave processing

Some advanced systems use delayed heave algorithms. These algorithms process motion data with a short time delay to improve accuracy. This method is particularly effective in irregular wave conditions.

3 – Active Heave Compensation (AHC)

AHC systems use hydraulic or electric actuators to physically counteract vertical motion. They are widely used on cranes, drilling rigs, and remotely operated vehicles (ROVs). By adjusting equipment position continuously, they maintain stability despite wave-induced heave.

4 – Passive Heave Compensation (PHC)

PHC relies on mechanical systems like springs or dampers to absorb these forces. While less precise than AHC, it reduces motion impact in applications where full compensation is not required.

5 – Dynamic Positioning Systems (DP)

DP systems integrate data with thruster control. They stabilize the vessel’s overall position and reduce motion effects. When combined with other sensors, DP enhances station-keeping performance in offshore operations.

6 – Post-Processing corrections

In hydrographic surveys, these corrections are often applied after data collection. Motion sensor data is synchronized with sonar or lidar measurements. Software then removes heave effects to produce accurate bathymetric maps.

Explore our range of maritime solutions designed for real-time wave monitoring.