GRYFN’s success story: Achieving precision and efficiency with Quanta Micro

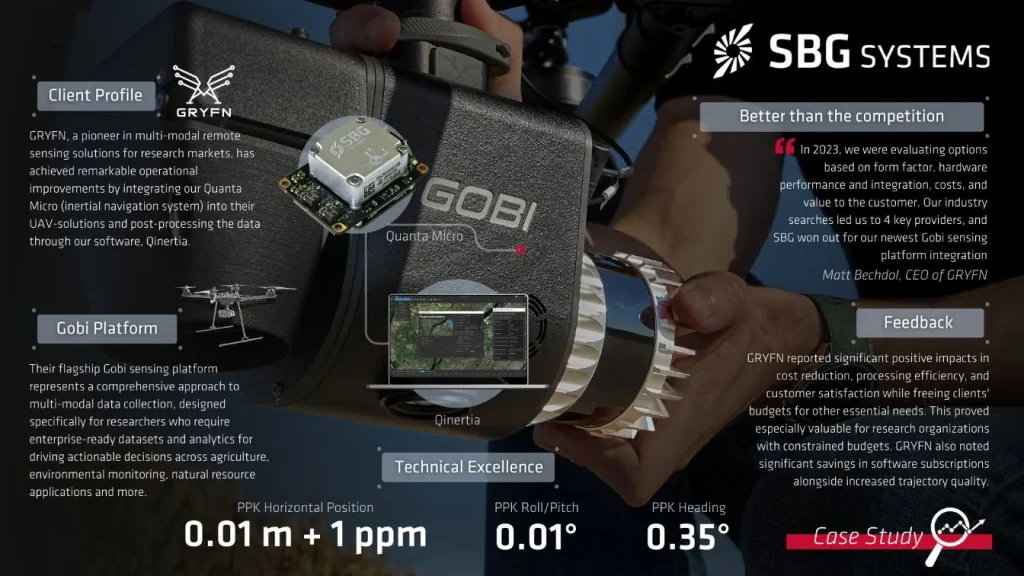

GRYFN, a pioneer in multi-modal remote sensing solutions for research markets, has achieved remarkable operational improvements by integrating our Quanta Micro (inertial navigation system) into their UAV-solutions and post-processing the data through our software, Qinertia.

This collaboration has delivered for the end-user centimeter-level accuracy, 10% cost reduction over five years, and a streamlined workflow integration.

“On a scale of 0 to 5, the product, software, support, and costs meet or exceed expectations – a 5.” | Matt Bechdol, CEO of GRYFN.

Company’s core: Multi-modal remote sensing

GRYFN specializes in research-ready, high-precision, multi-modal remote sensing UAV solutions that simultaneously acquire high-resolution RGB, LiDAR, and hyperspectral data.

Their flagship Gobi sensing platform represents a comprehensive approach to multi-modal data collection, designed specifically for researchers who require enterprise-ready datasets and analytics for driving actionable decisions across agriculture, environmental monitoring, natural resource applications, or wherever accurate active and passive remote sensing is demanded.

And all this qualified demand led them to our solutions so they could enhance their platform while reducing operational complexity and costs for customers.

The requirements that match our solutions

GRYFN’s demanding applications required an inertial navigation solution capable of delivering centimeter-level precision and accuracy for real-time (RTK) and post-processed (PPK) trajectory data.

The integration of hyperspectral imaging, LiDAR, and RGB sensors on UAV platforms presents unique technical challenges.

Each sensor modality captures data at different rates and requires precise positioning information to enable accurate data fusion and analysis.

Not surprisingly, GRYFN’s requirements also needed to include:

- High-quality GNSS-INS data with at least 2cm accuracy or better for reliable direct georeferencing.

- Easy-to-integrate software with command-line interface and SDK support for post-processing workflows.

- Open licensing infrastructure to reduce deployment complexity for distributed research customers.

- Cost-effective solutions, particularly, important for research institutions with multiple deployment scenarios.

- Responsive technical support to address integration challenges quickly.

- Compact form factor with accuracy, reliability, size, and weight optimization.

“In 2023, we were evaluating options based on form factor, hardware performance and integration, costs, and value to the customer. Our industry searches led us to 4 key providers, and SBG won out for our newest Gobi sensing platform integration,” explains, Matt.

Quanta Micro integration and performance

We addressed GRYFN’s requirements through our Quanta Micro solution, an ultra-compact, high-performance GNSS-aided inertial navigation system specifically designed for drone remote sensing applications where precision and space constraints are critical.

- GRYFN integrated Quanta Micro navigation system, operating in dual antenna mode and integrated into a custom PCB. This configuration enables the system to output GNSS-INS data to multiple sensors simultaneously, supporting GRYFN’s multi-modal sensing requirements.

- Here the Quanta Micro’s form factor proved excellent for GRYFN’s compact, multimodal sensor integration requirements.

- The dual antenna configuration enhanced heading accuracy and system reliability, critical factors for precise trajectory determination in research applications.

- The hardware integration process was streamlined by our design approach, allowing GRYFN to focus on their core remote sensing capabilities rather than navigation system complexities.

One of the highlights we’re proud to emphasize in every partnership like this is our commitment to providing closer support, especially during phases when the company is still testing and determining the best way to integrate the technology.

“The SBG teams were responsive to questions and technical discussions as we performed initial comparisons and tests, and support was excellent”, attests Matt.

Qinertia’s user-friendly x-factor

Furthermore, the integration of our post-processing software, Qinertia, with the GRYFN Processing Tool software delivered significant workflow improvements for GRYFN’s operations.

The team found Qinertia user-friendly and straightforward, with comprehensive documentation providing concise instructions and explanations for each processing step and setting.

This software approach eliminated the need to download RINEX data, unlike competitive solutions, streamlining the processing workflow. They also praised the API documentation quality, noting they required minimal support for software-side integration. This self-service capability reduced implementation time and ongoing support requirements.

Measurable results and performance improvements

GRYFN’s integration with our systems has delivered measurable operational improvements across multiple dimensions.

“Ease of adoption for customers has reduced support requirements, saving time and focus,” highlights Matt.

In a nutshell, significant positive impacts were observed in cost reduction, processing efficiency, and customer satisfaction by also freeing their budget for other essential needs.

That proved particularly valuable for research organizations operating with constrained budgets. GRYFN also specifically noted significant savings in software subscriptions coupled with increased trajectory quality.

Conclusion: Competitive advantage development

Quanta Micro and Qinertia have strengthened GRYFN’s competitive position through:

- Improved cost structure.

- Enhanced performance capabilities.

- Streamlined customer experience.

It’s always important to highlight that these improvements translate directly to enhanced customer satisfaction and retention.

GRYFN’s case study validates that precision navigation technology can deliver both technical performance and business value when properly integrated into sophisticated remote sensing platforms.

With this partnership, we provided a compelling reference for achieving operational excellence in UAV-based data collection.

Quanta Micro

Quanta Micro is a compact, high-performance GNSS-aided inertial navigation system designed for space-constrained applications requiring exceptional accuracy and reliability.

It integrates a survey-grade IMU with a multi-frequency, quad-constellation GNSS receiver and advanced sensor fusion algorithms to deliver centimeter-level positioning and precise orientation in challenging environments.

The system features dual-antenna capability for optimal heading performance in low-dynamic conditions, while maintaining exceptional single-antenna operation for UAV payloads and constrained applications.

Ask a quotation for Quanta Micro

Do you have questions?

Welcome to our FAQ section! Here, you’ll find answers to the most common questions about the applications we showcase. If you don’t find what you’re looking for, feel free to contact us directly!

What is the difference between IMU and INS?

The difference between an Inertial Measurement Unit (IMU) and an Inertial Navigation System (INS) lies in their functionality and complexity.

An IMU (inertial measuring unit) provides raw data on the vehicle’s linear acceleration and angular velocity, measured by accelerometers and gyroscopes. It supplies information on roll, pitch, yaw, and motion, but does not compute position or navigation data. The IMU is specifically designed to relay essential data about movement and orientation for external processing to determine position or velocity.

On the other hand, an INS (inertial navigation system) combines IMU data with advanced algorithms to calculate a vehicle’s position, velocity, and orientation over time. It incorporates navigation algorithms like Kalman filtering for sensor fusion and integration. An INS supplies real-time navigation data, including position, velocity, and orientation, without relying on external positioning systems like GNSS.

This navigation system is typically utilized in applications that require comprehensive navigation solutions, particularly in GNSS-denied environments, such as military UAVs, ships, and submarines.

How are drones used for agricultural purposes?

Drones are increasingly used in agriculture to enhance crop management and boost productivity. Equipped with high-resolution cameras and sensors, farming drones provide aerial imagery and data on crop health, soil conditions, and field variability. This allows farmers to monitor large areas quickly and identify issues such as pest infestations, nutrient deficiencies, and water stress with precision.

Drones in agriculture are used for precision application of inputs like fertilizers, pesticides, and herbicides. By targeting specific areas with accuracy, drones reduce waste and minimize environmental impact. Additionally, they assist in agriculture drone mapping and planning field layouts, and monitoring crop growth and yields over time.

Overall, farming drones offer a cost-effective and efficient way to gather critical information, make informed decisions, and implement targeted interventions, leading to improved crop management and resource use.

What is georeferencing in aerial surveying?

Georeferencing is the process of aligning geographic data (such as maps, satellite images, or aerial photography) to a known coordinate system so that it can be accurately placed on the Earth’s surface.

This allows the data to be integrated with other spatial information, enabling precise location-based analysis and mapping.

In the context of surveying, georeferencing is essential for ensuring that the data collected by tools like LiDAR, cameras, or sensors on drones is accurately mapped to real-world coordinates.

By assigning latitude, longitude, and elevation to each data point, georeferencing ensures that the captured data reflects the exact location and orientation on the Earth, which is crucial for applications such as geospatial mapping, environmental monitoring, and construction planning.

Georeferencing typically involves using control points with known coordinates, often obtained through GNSS or ground surveying, to align the captured data with the coordinate system.

This process is vital for creating accurate, reliable, and usable spatial datasets.

What is the difference between RTK and PPK?

Real-Time Kinematic (RTK) is a positioning technique where GNSS corrections are transmitted in near real time, typically using an RTCM format correction stream. However, there can be challenges in ensuring the GNSS corrections, specifically their completeness, availability, coverage, and compatibility.

The major advantage of PPK over RTK post processing is that the data processing activities can be optimized during post-processing, including forward and backward processing, whereas in real-time processing, any interruption or incompatibility in the corrections and their transmission will lead to lower accuracy positioning.

A first key advantage of GNSS post-processing (PPK) vs. real time (RTK) is that the system used on the field does not need to have a datalink/radio to feed the RTCM corrections coming from the CORS into the INS/GNSS system.

The main limitation to post processing adoption is the requirement of the final application to act on the environment. On the other hand, if your application can withstand the additional processing time needed to produce an optimized trajectory, it will greatly improve the data quality for all your deliverables.